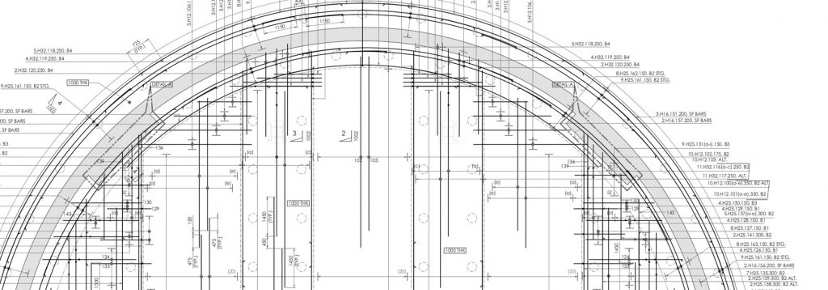

RebarCAD’s success is due to its advanced detailing features and technical excellence, which includes integration with fabrication software. RebarCAD can detail any structure (including those with irregular geometry) and has been successfully used on all sorts of building, transportation, water, process and power projects including many precast concrete elements.

Principle benefits:

- Easy to use and fully integrated with AutoCAD to make importing outlines simple and detailing vastly more efficient

- As the world’s number one detailing software your bar bending schedules can be simply shared with steel fabricators in Excel or as a pdf

- Industry standard solution with a large user base in LinkedIn, making recruitment easier

- Powerful editing and revision features save you valuable time when duplicating, editing or correcting

- Reduced checking required and virtual elimination of errors since the BBS is continuously updated automatically

- International versions for UK, North America, India and South Africa

- The automated BBS reduces waste from off-cuts

- Automatic RC detailing macros for stair flights, pile caps, pad footings, octagonal bases, simple beams, simple columns, slab panels, pad bases, panels and circular bar arrangements

- BBS and the AutoCAD working environment are easily customisable

- Bar Mark project management, matches bar marks across multiple drawings

- Support for Over Stock Length Bars (OSL)

- RebarCAD supports most leading coupler manufacturers

- Revisions are marked and updated automatically

- The “combine and compact” feature groups identical bars so they have the same label to save time on site

- The bar bending schedule links directly to production software and machinery such as PEDAX and Schnell

- CADS offer a combination of training, support and software maintenance: CADScover

Try out the software for yourself

Want to see how RebarCAD works?

Speak to our team